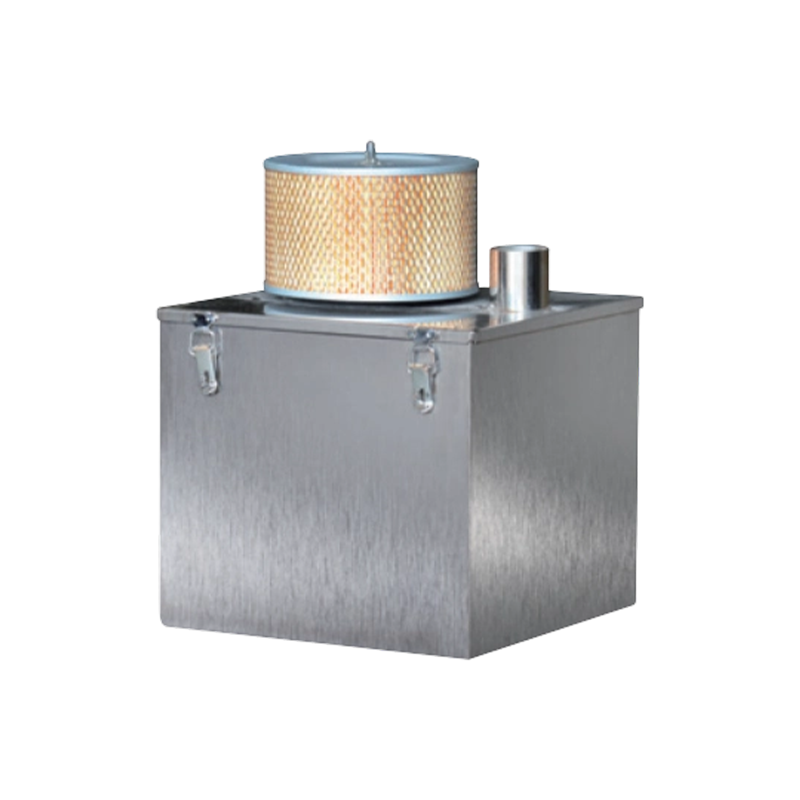

Air Cooled Cased Industrial Chiller

The industrial chiller is specially designed on purpose to be used in the plastic manufacturing industry. This equipment can greatly raise the working efficiency of manufacturing machines and obviously improve the quality of products and thus, earnmore profit. Compressor is used "COPELAND" brand which made in the USA.

Features

·The inside safety protection can guarantee the long-lasting performance of the chiller. The pump is made in Taiwan and all parts of the cooling system are imported from the USA. Mexico. Denmark and Japan.

·Equipped with a shellpipe condenser and stainless steel cased evaporator, which are quite easy to clean and maintain. Equipped with an automatic water supply device in the water tank.

·Larger models than model XC-20 are assembled with 2 sets or 4 sets of compressors, so they are able to be used separately or together to reduce resource waste.

·Complete with safety protection and error indication system, including compressor overload, protection, pump overload protection, high pressure and low pressure protection and phase failure protection

·Equipped with figure intellectualized temperature controls, which can accurately measure and control water temperature within the range of 5°C~35℃.

Applied Machinery

Cooling system of oil temperature, ultrasonic, high frequency machinery. Cooling system of injection molding machinery. Cooling system of blow molding machinery. Cooling system of the extruder.

Air-cooled cased chiller with board-type evaporator is suitable for districts with a lack of water resources and districts with poor water quality.

Additional equipment for the option

·Starter of the timer switch.

·Large type of water filter.

·Protection switch to prove the electric leakage.

·Cooling tower and pump.

-

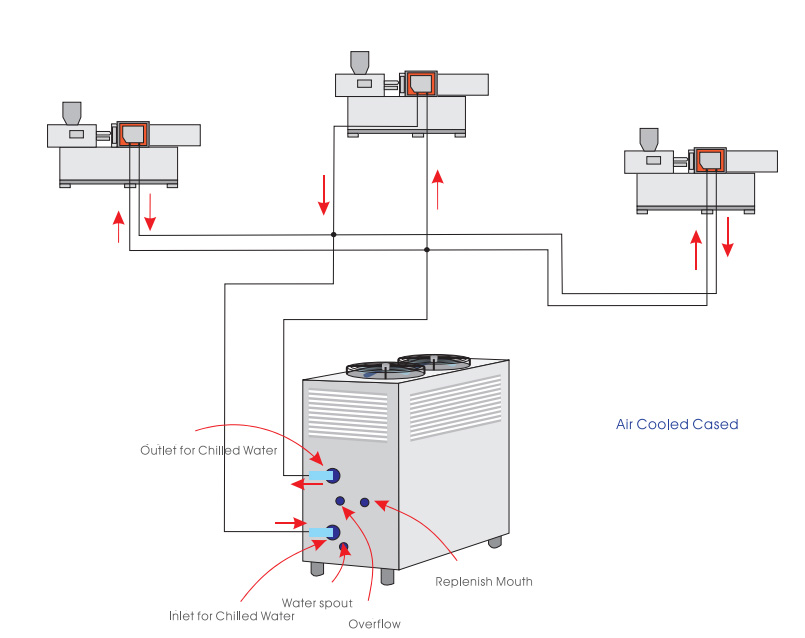

Illustration for installing xinre industrial chiller

-

Additional equipment for option

- Starter of the timer switch.

- Large type of water filter.

- A protection switch to prevent the electric leakage.

- Cooling tower and pump.

Product Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Specifications | XC-01ACI | XC-03ACI | XC-05ACI | XC-08ACI | XC-10ACI | XC-12ACI | XC-15ACI | XC-20ACI | XC-25ACI | XC-30ACI | XC-40ACI | XC-50ACI | XC-100ACI |

| Cooling capacity(Kcal/h) | 2300 | 7660 | 12560 | 19730 | 26000 | 34400 | 38860 | 52400 | 59740 | 77700 | 103200 | 12780 | 243000 |

| Compressor | All-closed Vorticity | Screw bar compressor | |||||||||||

| Compressor power(Kw) | 0.8 | 2.5 | 4.4 | 7 | 9 | 10.2 | 13.4 | 18 | 20.4 | 26.8 | 35 | 40 | 74 |

| Refrigerant | R22(R407,R502 Eco-friendly optional) | ||||||||||||

| Chi1ledwater pump power(Kw) | 0.37 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 4 | 7.5 | 7.5 | 8 |

| Max flow rate of chilled water(L/min) | 90 | 90 | 115 | 115 | 217 | 217 | 315 | 315 | 315 | 400 | 600 | 600 | 900 |

| Max pressure(m) | 22 | 22 | 28 | 28 | 25 | 25 | 25 | 26 | 26 | 50 | 55 | 55 | 60 |

| Flow water inlet and outlet pipe | 1” | 1” | 1.5” | 1.5” | 1.5” | 1.5” | 1.5” | 1.5” | 1.5" | 2.5” | 3" | 3” | 5” |

| Cooling fan power(Kw) | 0.1 | 0.25 | 0.5 | 0.5 | 0.5 | 0.5 | 1 | 1.5 | 1.5 | 1.5 | 3.2 | 3.2 | 5 |

| Size length(mm) | 680 | 030 | 1100 | 1220 | 1220 | 1220 | 1220 | 1900 | 2300 | 2300 | 2000 | 2100 | 3600 |

| Size width(mm) | 460 | 680 | 700 | 800 | 930 | 930 | 1050 | 1070 | 120 | 1220 | 1200 | 1300 | 1800 |

| Size height | 840 | 1270 | 1400 | 1450 | 1600 | 1600 | 1600 | 2030 | 2030 | 2000 | 2100 | 2100 | 1800 |

| Water tank capa. | 20 | 53 | 88 | 120 | 200 | 200 | 240 | 380 | 380 | Non-water box(dry-type) | |||

| Weight | 35 | 180 | 240 | 300 | 360 | 380 | 460 | 680 | 700 | 820 | 1100 | 1400 | 2800 |

EN

EN

English

English