ABOUT US

View More

Our Products Are Complete And We Provide One-Stop Services.

Ningbo Beilun Xinre Machinery Manufacturing Co., Ltd.

is located in Beilun, Ningbo, Zhejiang Province, the global manufacturing centre of plastic injection moulding machinery, which is east of Ningbo Port. It is in a superior location with convenient traffic. After ten years’ strenuous efforts, the products of the brand “Xinre” have spread to most provinces and cities in China, as well as over 50 countries on six continents throughout the world. Against the background of the global economy, being affected by the economic impulse of the emerging markets in the world, Xinre has expanded its vision and layout to the whole world.-

2002

2002Was Founded In

-

23+

23+Industry Experience

-

**+

**+Number of Employees

-

0+

0+Verseas Market

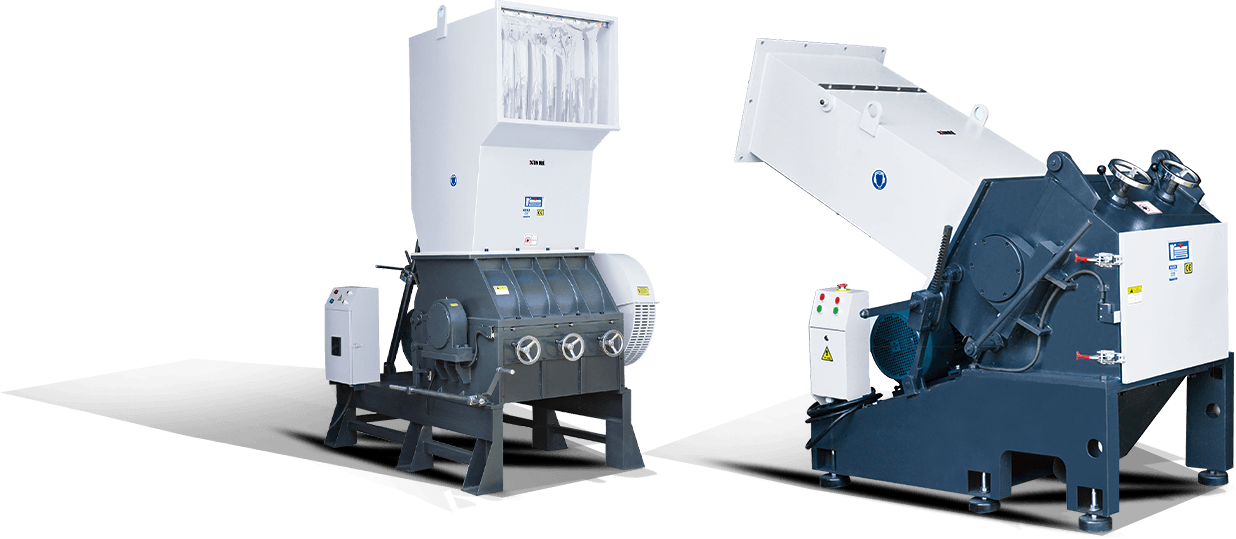

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

- Crushing and Recycling

-

Quality

QualityWe possess a full range of in-house equipment, from blank manufacturing to final assembly, ensuring stringent quality control throughout the entire production process.

-

Production Capacity

Production CapacityWe maintain ample production capacity and exercise strong control over raw material pricing, quality, and the stability of supply.

-

Industry Experience

Industry Experience“XINRE” will face new challenges and opportunities to plough through and create a magnificent chapter in the 21st century together with customers.

-

Global Reach

Global ReachOur products meet international standards and are primarily exported to Europe, the United States, Malaysia, Singapore, and South Korea.

EN

EN

English

English 中文简体

中文简体