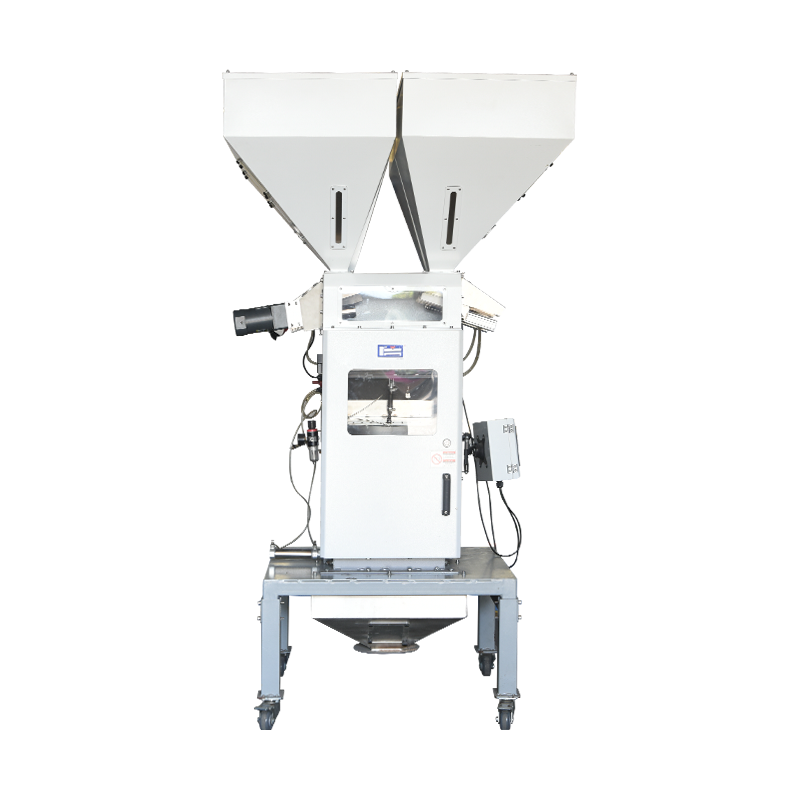

Gravimetric Blenders

The XGB Series Gravimetric Blenders are designed for weighing and blending various raw materials in precise weight ratios for use with plastic injection, extrusion, or blow molding machines. This series features a PLC-controlled system with adaptive algorithms that automatically calibrate during initial startup to ensure accuracy, offering intuitive and user-friendly operation.

High-precision conversion modules minimize batch mixing ratio errors to ±0.1%-0.5% (depending on the set ratio).

Select the appropriate machine based on material variety and hourly throughput requirements, with processing capacities ranging from 50 to over 3000 kilograms per hour.

Special Features

·All materials are uniformly mixed after gravity metering, ensuring strict precision control.

·Advanced batching technology effectively controls and measures the ratio of each processed ingredient;

·Automatic repeat calibration function automatically corrects and adjusts after each weighing to guarantee batching accuracy;

·Capable of simultaneously processing up to 6 ingredients:

·Modular, detachable structure design for easy cleaning;

·Alarm history logging capability;

·Standard configuration includes machine-mounted installation (with standard base and manual shut-off gate);

·Optional USB data export function to save and record mixing ratios for production quality management;

·When modified to European safety circuit standards, the model designation is suffixed with “CE”;

·Recipe storage function capable of saving up to 20 recipes.

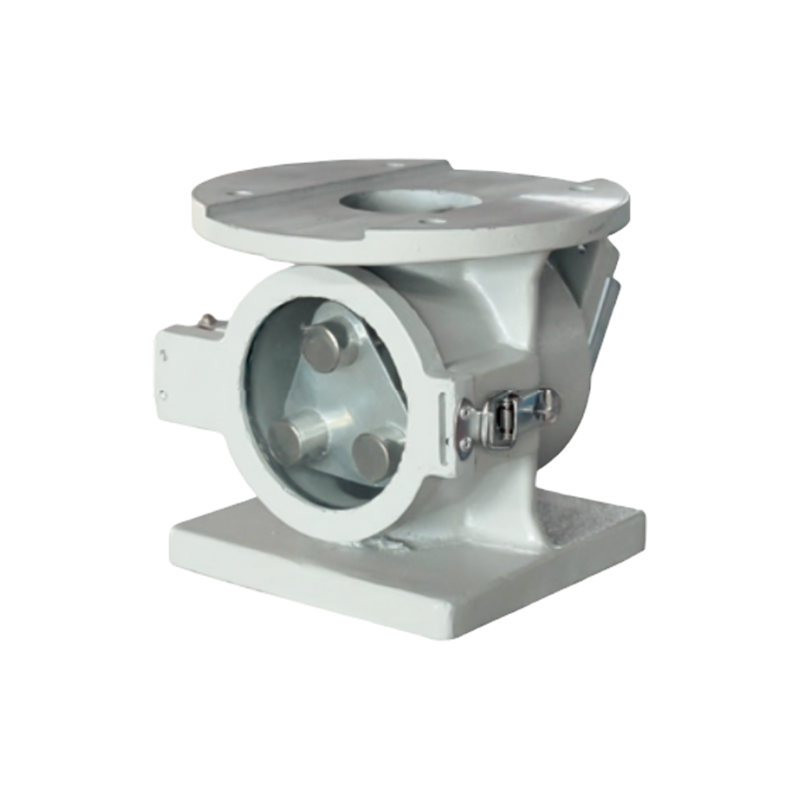

Optional Project

You need optional mounting frame, pneumatic discharge valve, storage bin and suction box when the machine is used for

ground installation.

Note

·The mixing ratio error is the difference between the setting percentage and the actual percentage

·The knife metering valve is suitable for the proportion of 5% and above, the mixing ratio error can be controlled in ±0.3-0.5%.

·Screw or micro-meter suitable for 5% to 0.5% ratio, mixing ratio error can be controlled in ±0.2%;

·The maximum throughput and the mixing ratio error data are based on the continuous density of 0.8kg/L and the diameter of 3-4 mm.

·The maximum output will vary according to the number and proportion of the metering group;

·Please ensure the valve pressure 6kgf/cm²,Standard voltage: HGB-5 and below models 1 Phase, 220V 50 Hz, HGB10 and above models 3 Phase, 38ov 50Hz;

·Have any special needs, please contact us.

·Specifications are subject to change without prior notice.

Product Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Modek RGB | XGB-50 | XGB-100 | XGB-200 | XGB-400 | XGB-600 | XGB-800 | XGB-1200 | XGB-2000 | XGB-2500 | XGB-3000 |

| Base Material Capacity | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Mixing Capacity | 50 | 100 | 200 | 400 | 600 | 800 | 1200 | 2000 | 2500 | 3000 |

| Batch Weight | 0.6 | 1.2 | 2.2 | 4.5 | 6 | 8 | 12 | 20 | 25 | 30 |

| Primary Material Moisture Range | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 | 5~100 |

| Additive Mixing Range | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 |

| Primary Material Hopper Volume | 18 | 25 | 32 | 45 | 70 | 100 | 130 | 160 | 180 | 230 |

| Additive Hopper Volume | 18 | 25 | 32 | 45 | 70 | 100 | 130 | 160 | 180 | 230 |

| Mixing Drum Volume | 6 | 6 | 20 | 20 | 40 | 40 | 80 | 80 | 100 | 180 |

| Power Specifications | Φ1 | Φ1 | Φ1 | Φ1 | Φ1 | Φ1 | Φ3 | Φ3 | Φ3 | Φ3 |

| 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | 230/50 | |

| Total Power | 0.12 | 0.12 | 0.25 | 0.25 | 0.55 | 0.55 | 1.5 | 1.5 | 1.5 | 3 |

| Compressed Air | 6-8 | |||||||||

| Noise Level | 75 | |||||||||

EN

EN

English

English