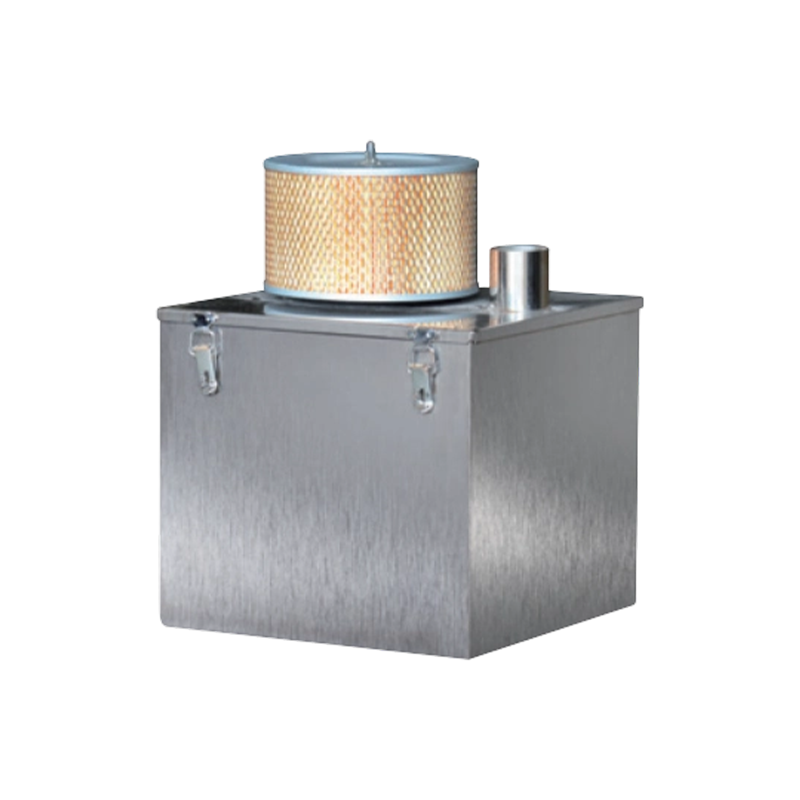

Honeycomb Dehumidifiers

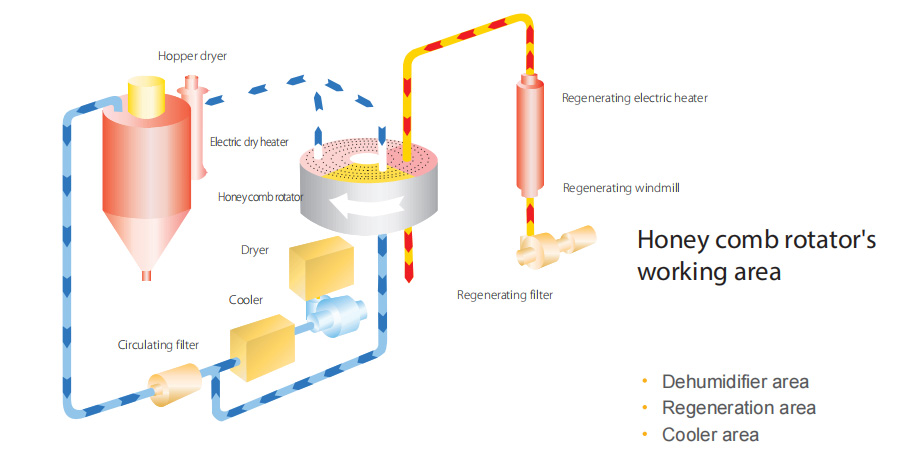

With high efficiency, XD series honeycomb rotation cylinder dehumidifier is mainly used for dehumidifying operations on engineering plastics with strong hygroscopic properties. The display screen shows the reproducing temperature setting and the actual temperature.

The body consists of ceramic honeycombs made of ceramic fiber and organic additive, and molecular sieve and silicon glue as basic material crystal sintered by high temperature with surface hard force to be attracted to the inner of the honeycombs. So unlikely as general cylinder-type or rotation tray type, the powder particles produced by molecular nodes aging to be blown into the drying tube to pollute the plastic, and furthermore, its endless using life and washability are unlikely, as general molecular nodes aging and become saturated should be replaced often. The water content will be sucked immediately when the moisture return wind through the numerous micro holes of the cylinder honeycombs. So they have been dehumidified completely and have been fully dried with a very low dew point. The principles of reproduction and dehumidification are the same and are carried out simultaneously; only the reproduced wind blows in has reverse direction.

Features

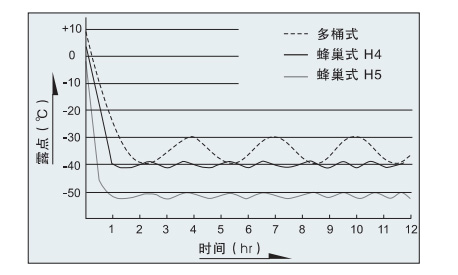

·The dew point of dried wind hit -50°C.

·Main power switch with mechanical interlock function.

·The dehumidification system adopts a double cooler structure, which can guarantee very low return wind temperature and dew point.

-

Schematic Diagram

-

Dew point eect comparison

Product Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Model | Regen.heater power (kw) |

Dry airflow (m³hr) |

Weight (kg) |

External size (mm) |

Pipesize (lnch) |

| XD-90H | 3.5 | 90 | 156 | 900x520x1700 | 2" |

| XD-120H | 3.5 | 120 | 190 | 900x620x1700 | 2" |

| XD-150H | 4 | 150 | 220 | 1300x700x1700 | 2.5" |

| XD-200H | 5.4 | 200 | 240 | 1300x700x1700 | 2.5" |

| XD-300H | 7.2 | 300 | 260 | 1300x700x1800 | 3" |

| XD-400H | 7.2 | 400 | 380 | 1300x700x1800 | 4” |

| XD-500H | 10 | 500 | 400 | 1500x1000x1900 | 4" |

| XD-700H | 10 | 700 | 410 | 1500x1000x1900 | 4” |

| XD-1000H | 15 | 1000 | 500 | 1500x1200x1900 | 5" |

| Dew point | Rrelative humidify (%) |

Moisture content (PPM) | Moisture content (%) |

| +20 | 100 | 23.072 | 2.307 |

| +10 | 52.50 | 12.117 | 1.212 |

| 0 | 26.1 | 6.027 | 0.603 |

| -10 | 11.20 | 2.574 | 0.257 |

| -20 | 4.40 | 1.025 | 0.103 |

| -30 | 1.60 | 378 | 0.038 |

| -40 | 0.60 | 128 | 0.013 |

| -50 | 0.20 | 39 | 0.004 |

| Raw material | Drying | Drying time |

Specific heat |

Material proportion |

Water ratio before dehumidifying |

Water ratio after dehumidifying |

Drying capacity(kg/hr) | ||||||||

| c | hr | j/kg℃ | kg/dm³ | % | % | XD-90H | XD-120H | XD-150H | XD-200H | XD-300H | XD-400H | XD-500H | XD-700H | XD-1000H | |

| ABS | 80 | 2-3 | 0.34 | 0.6 | 0.3 | 0.02 | 27 | 35 | 71 | 105 | 180 | 210 | 285 | 355 | 425 |

| CA | 75 | 2-4 | 0.5 | 0.5 | 1 | 0.02 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 |

| CAB | 75 | 2-3 | 0.5 | 0.5 | 0.8 | 0.02 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 |

| CP | 75 | 2-3 | 06 | 0.6 | 1 | 0.02 | 27 | 35 | 71 | 106 | 180 | 210 | 285 | 355 | 425 |

| LCP | 150 | 4 | 0.6 | 0.6 | 0.04 | 0.02 | 20 | 27 | 55 | 80 | 135 | 160 | 210 | 265 | 320 |

| POM | 100 | 2 | 0.35 | 0.6 | 0.2 | 0.02 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 |

| PMMA | 80 | 3 | 0.35 | 0.65 | 0.5 | 0.02 | 29 | 38 | 77 | 115 | 192 | 230 | 307 | 383 | 460 |

| ILNOMER | 90 | 3-4 | 0.55 | 0.5 | 0.1 | 0.04 | 17 | 22 | 44 | 66 | 111 | 133 | 177 | 220 | 265 |

| PA6/6.6/6.10 | 75 | 4-6 | 0.4 | 0.65 | 1 | 0.05 | 14 | 19 | 38 | 58 | 96 | 115 | 153 | 192 | 239 |

| PA11 | 75 | 4-5 | 0.58 | 0.65 | 1 | 0.05 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 |

| PA12 | 75 | 4-5 | 0.28 | 0.65 | 1 | 0.05 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 |

| PC | 120 | 2-3 | 0.28 | 0.70 | 0.3 | 0.01 | 31 | 41 | 83 | 124 | 206 | 250 | 330 | 413 | 495 |

| PU | 90 | 2-3 | 0.45 | 0.65 | 0.3 | 0.02 | 29 | 38 | 77 | 115 | 190 | 230 | 307 | 383 | 460 |

| PBT | 130 | 3-4 | 0.3-0.5 | 0.7 | 0.2 | 0.02 | 23 | 31 | 62 | 93 | 155 | 186 | 248 | 310 | 372 |

| PE | 90 | 1 | 0.55 | 0.6 | 0.01 | <0.01 | 80 | 106 | 212 | 318 | 531 | 637 | 850 | 1062 | 1275 |

| PEI | 150 | 3-4 | 0.6 | 0.6 | 0.25 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PET | 160 | 4-6 | 0.3-0.5 | 085 | 0.2 | 0.02 | 19 | 25 | 50 | 75 | 125 | 150 | 200 | 250 | 300 |

| PETG | 70 | 3-4 | 0.6 | 0.6 | 0.5 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PEN | 170 | 5 | 085 | 085 | 0.1 | 0.05 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 |

| PES | 150 | 4 | 0.7 | 0.7 | 0.8 | 0.02 | 23 | 30 | 60 | 90 | 150 | 180 240 | 300 | 360 | |

| PMMA | 80 | 3 | 0.65 | 0.65 | 0.5 | 0.02 | 29 | 38 | 77 | 115 | 190 | 230 | 310 | 385 | 460 |

| PPO | 110 | 1-2 | 0.4 | 0.5 | 0.1 | 0.04 | 33 | 44 | 88 | 133 | 220 | 265 | 355 | 440 | 530 |

| PPS | 150 | 3-4 | 0.6 | 0.6 | 0.1 | 0.02 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 |

| PI | 120 | 2 | 0.27 | 0.6 | 0.4 | 0.02 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 |

| PP | 90 | 1 | 0.46 | 0.5 | 0.1 | 0.02 | 66 | 88 | 180 | 265 | 442 | 530 | 710 | 885 | 1060 |

| PS(GP) | 80 | 1 | 0.28 | 0.5 | 0.1 | 0.02 | 66 | 88 | 180 | 265 | 442 | 531 | 708 | 882 | 1062 |

| 345PSU | 120 | 3-4 | 0.31 | 0.65 | 0.3 | 0.02 | 22 | 29 | 60 | 85 | 145 | 173 | 230 | 290 | 345 |

| PVC | 70 | 1-2 | 0.2 | 0.5 | 0.1 | 0.02 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 |

| SAN(AS) | 80 | 1-2 | 0.32 | 0.5 | 0.1 | 0.05 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 |

| TPE | 110 | 3 | 0.7 | 0.7 | 0.1 | 0.02 | 30 | 40 | 85 | 125 | 205 | 250 | 330 | 413 | 495 |

| (1) Useing indenpendent dry hopper (2) Under the 20℃ atmospheric temperatures and 65% relatively temperatures, the water containing less than 0.005% of ter drying. |

|||||||||||||||

EN

EN

English

English