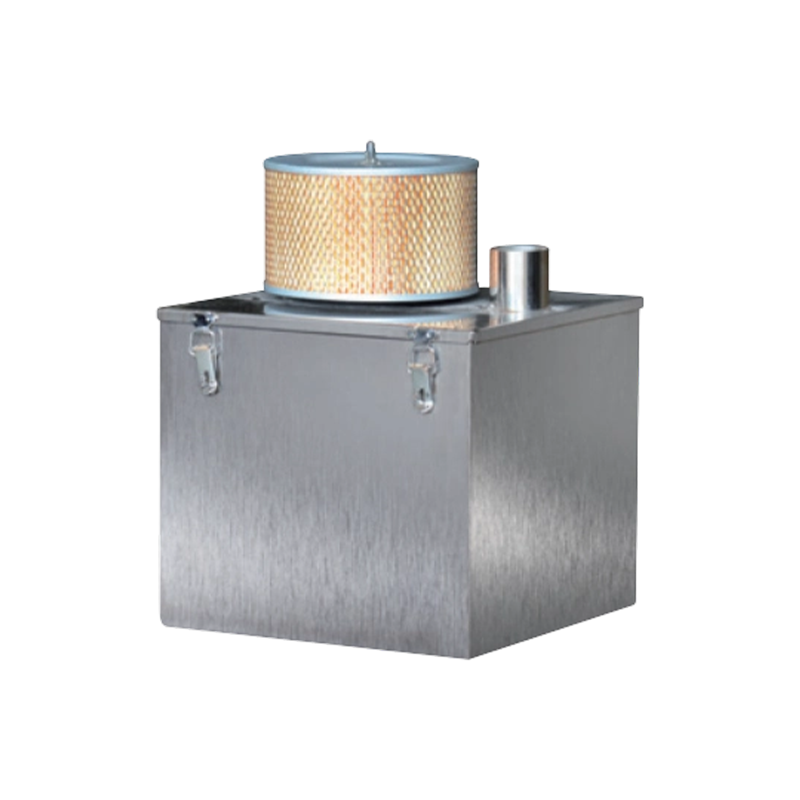

Mold Sweat Dehumidifiers

Condensation shows that there is water content gas when the temperature of the mold surface is lower than the dew point temperature of the surrounding air, which influences the product quality and product efficiency. Meanwhile, this phenomenon erodes the mold surface and results in environmental pollution. The machine uses the honeycomb running system to dehumidify, which always ensures the mould maintains 0-10 low dew point air environment. This feature which doesn't produce condensation, can't be subject to seasonal changes and reduces the rate of defective and waste products.

XMD mold dehumidifier is mainly used in plastic and rubber molding. As the mold uses the cooling water to reduce the molding cycle, which results in the problem of water condensation, it is most applicable for PET and XMD bottle shooting out, particularly. 24-hour automatic operation timing setting and automatic malfunction display.

·Use P.L.D. temperature control system with regeneration temperature settings and an actual temperature display screen.

·Honeycomb designer with dehumidification and stable dryness.

·Motor overload and reverse alarm function.

Features

·The total power switch with a mechanical chain function

·Return air cooling and filtering function

·Choice digital dew point detector attached to a high dew point and alarm instructions

·In normal atmospheric conditions, it can control humidity precisely throughout the year

·Prolong the mould's life, reduce erosion, improve the rate of good quality product

·Dry wind temperature is about 30 °C from the exit to mould, which doesn't lean to the surrounding temperature of mould is too low, so that the injection machine window condensate

·Random with removable return air collector can be confined to achieve the cycle of applications, particularly applicable to the tropical climate environment

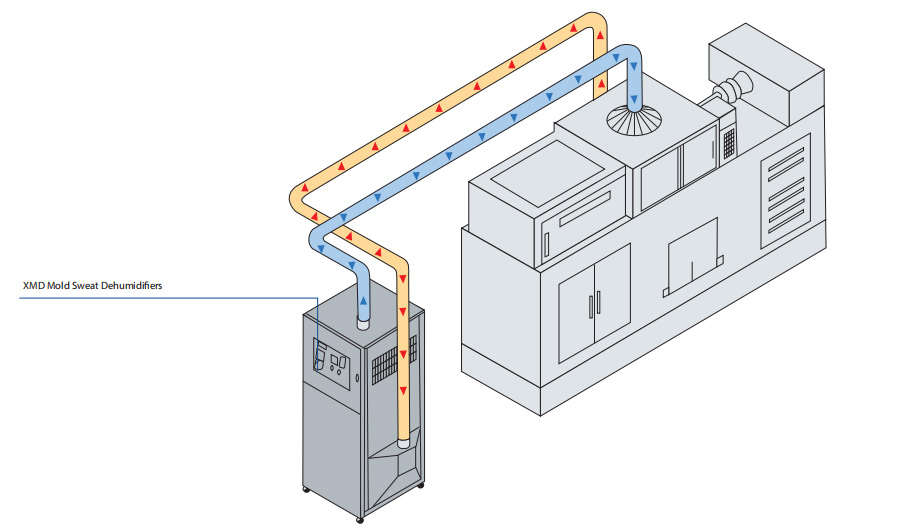

Product application diagram

Product Parameters

We can design and develop according to the needs of our customers to meet the requirements of different clients.

| Model | XMD-500H | XMD-1000H | XMD-1500H | XMD-2000H | |

| Dry windmill(kw) | 2.2 | 3 | 3x2 | 3x2 | |

| Renewable windmill(kw) | 0.55 | 0.75 | 0.55x2 | 0.75x2 | |

| Dry wind flow(m³/hr) | 500 | 1000 | 1500 | 2000 | |

| Renewable heating(kw) | 5 | 7.2 | 12x2 | 12x2 | |

| Dry wind piping size | 4” | 5” | 8” | 8” | |

| Renewable wind piping size | 2” | 2.5” | 3” | 3” | |

| Cooling faucet size | 3/4”PT | 3/4”PT | 3/4”PT | 3/4”PT | |

| Dry air temperature(℃) | 30 | 30 | 30 | 30 | |

| The average dew point temperature(℃) | -10 | -10 | -10 | -10 | |

| Fan pressure(Pa) | 3000 | 3000 | 3500 | 3500 | |

| Cooling water flow(L/M) | 50 | 50 | 100 | 100 | |

| Water pressure(kgf/cm²) | 3~5 | 3~5 | 3~5 | 3~5 | |

| External size(mm) | H | 1850 | 2000 | 1990 | 2050 |

| W | 900 | 1100 | 1050 | 1150 | |

| L | 1100 | 1100 | 1950 | 2050 | |

| Weight(kg) | 250 | 300 | 500 | 600 | |

| Noised B(A) | 65 | 65 | 65 | 70 | |

EN

EN

English

English